Specifications

We offer a new generation of automatic lines for the production of bags and bags.

We offer a new generation of automatic lines for the production of bags and bags.

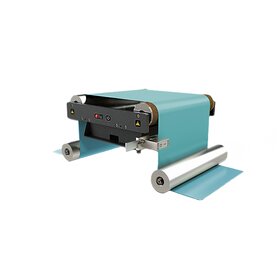

These are technically advanced automatic machines that are designed for the automatic production of bags from PP, LDPE, HDPE, non-woven fabric, etc. The machines are designed as cost-effective units requiring a minimum of operator intervention during the production of bags/bags.

The machines are certified in accordance with European Union regulations on safety, health protection and environmental protection - EC safety certificate (CE).

Features of the automatic lines offered by us:

Modules:

We use quality components from Siemens, Eaton, Festo, SMC, etc. (or we choose another brand that suits the customer best)