Specifications

- application with delicate materials

- very low moment of inertia

- low rolling resistance

- also suitable for applications with a large material width

- high resistance to deflection even under high loads

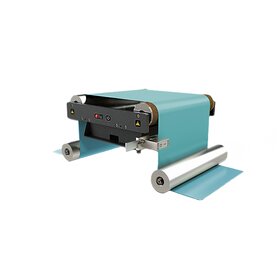

Rollers are used extensively in delicate material applications (such as carbon fiber winding) mainly due to their very low moment of inertia and low rolling resistance. Thanks to the ribbed construction, they are also suitable for applications with a large width of material, where they offer high resistance to deflection even under high loads.

We supply a wide range of guide rollers and aluminum profiles for all industrial applications. We offer profiles up to a length of 6 meters (anodized, straightened, deburred - butted on the faces), or we can deliver complete cylinders based on your requirements (storage, material tension, speed of rotation, etc.).

| Profile | Material | Outer ø | Internal ø | Weight per meter | Wall thickness | Surface finish | Surface roughness |

| 3RC48 | Aluminum AGS 6060 T5 | 48.3 mm | 27 mm | 1.2 kg | 1.5 mm | Anodization 15 μm | Ra 0.8 |

| 3RC60 | Aluminum AGS 6060 T5 | 60 mm | 31 mm | 1.8 kg | 1.8 mm | Anodization 15 μm | Ra 0.8 |

| 3RC80 | Aluminum AGS 6060 T5 | 81 mm | 40 mm | 3.2 kg | 2.5 mm | Anodization 15 μm | Ra 0.8 |

| 3RC100 | Aluminum AGS 6060 T5 | 100 mm | 45 mm | 5.3 kg | 3.5 mm | Anodization 15 μm | Ra 0.8 |

| 3RC120 | Aluminum AGS 6060 T5 | 121 mm | 60 mm | 6.5 kg | 4.5 mm | Anodization 15 μm | Ra 0.8 |

| 3RC130 | Aluminum AGS 6060 T5 | 130 mm | 70 mm | 10.6 kg | 6.5 mm | without | Ra 0.8 |

| 3RC145 | Aluminum AGS 6060 T5 | 145 mm | 70 mm | 9.3 kg | 4 mm | Anodization 15 μm | Ra 0.8 |

| 3RC200 | Aluminum AGS 6060 T5 | 201 mm | 106 mm | 16.5 kg | 5 mm | Anodization 15 μm | Ra 0.8-1.2 |

| 3RC230 | Aluminum AGS 6060 T5 | 230 mm | 152 mm | 18.9 kg | 5 mm | without | Ra 0.8-1.2 |